STONE MASTER PRODUCT CATEGORIES

WELCOME TO

STONE MASTER MOLDS

Stone Master Molds offers a wide variety of innovative stone and masonry accessory rubber molds for concrete, and we are constantly adding to our line of products.

Not only do we offer quality standard molds, but we also work with our clients to develop custom molds for their product lines. Contact us with your project and we will design and create a product to fulfill your needs.

Producing molds takes so much time and expense. Why spend both time and money manufacturing molds when you or your business is manufacturing concrete products? Let Stone Master Molds take that burden so that you get the quality molds you need and can focus on your project or growing your manufacturing business.

What’s New?

-

Stone Master Molds Rubber Molds for Concrete – River Rock Flat Mold

Rated 5.00 out of 5$125.95 -

Stone Master Molds Rubber Molds for Concrete, Cliff Stone 1-Step Corner Mold

Rated 5.00 out of 5$148.95 -

Stone Master Molds Rubber Molds for Concrete, Chiseled Edge Concrete Countertop Edge Form Liner, 10’L x 3”W x 2”D

Rated 5.00 out of 5$145.95 -

Stone Master Molds Rubber Mold for Concrete, Western Quick Fit Corner Molds

Rated 5.00 out of 5$148.95 -

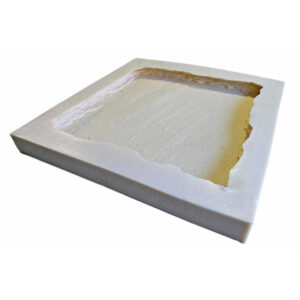

Stone Master Molds Rubber Molds for Concrete, Rustic Texture, Wall and Column Cap/Hearthstone/Paver Mold, 20.5″ x 20.5″ x 1.5″

Rated 5.00 out of 5$145.95 -

Stone Master Molds Rubber Molds for Concrete – Cliffstone Flat Mold

Rated 5.00 out of 5$136.95 -

Stone Master Molds Rubber Mold for Concrete, Western Quick Fit Flat Molds

Rated 5.00 out of 5$136.95 -

Stone Master Molds Rubber Molds for Concrete – Chiseled Edge Concrete Countertop Edge Form Liner, 8’L x 2”W x 2”D

Rated 5.00 out of 5$112.95

Are you a manufacturer of concrete products needing to order larger quantities or custom molds for concrete?

Show More

Show Less

Show More

Show Less

Good*****

Show More

Show Less

Show More

Show Less

Show More

Show Less

Show More

Show Less

nice mold

Show More

Show Less

Show More

Show Less

👍👌

Very good mold

Very good mold

Easy to take out from mold

Show More

Show Less

Show More

Show Less

Show More

Show Less

Show More

Show Less

Makes nice rocks for the money

Show More

Show Less

Made stone

Made stone

Show More

Show Less

Great quality

Great product*****

Show More

Show Less

Show More

Show Less

Show More

Show Less

Show More

Show Less

Great mould

Came out beautiful

Great product. Easy to use

Wow!!!!

did have trouble with bubbles

Still Have Questions?

We’re here to help! Let us guide you through the process.

Call our

experts at :

Are you a manufacturer of

concrete products needing to order

larger quantities or need a custom mold?

© 2024 Stone Master Molds – All Rights Reserved

Quick Links

Get in Touch

info@stonemastermolds.com

+1 833 665 3748

Stone Master Molds

740 State Highway 10

Kansas, OK 74347

© 2024 Stone Master Molds – All Rights Reserved

MY ACCOUNT

MY ACCOUNT