Stone Master Molds Rubber Molds for Concrete, Limestone 1-Step Corner Mold

Stone Master Molds Rubber Molds for Concrete, Limestone 1-Step Corner Mold

$132.95

- Create your own custom, stone veneer limestone corner molds

- Professional grade rubber mold will last for hundreds of pours

- Each of 3 mold versions has one-of-a-kind stones

- NO RELEASE AGENT necessary

- Matching Limestone flat molds available

- Made in the USA

Stone Master Molds Limestone Corner Mold

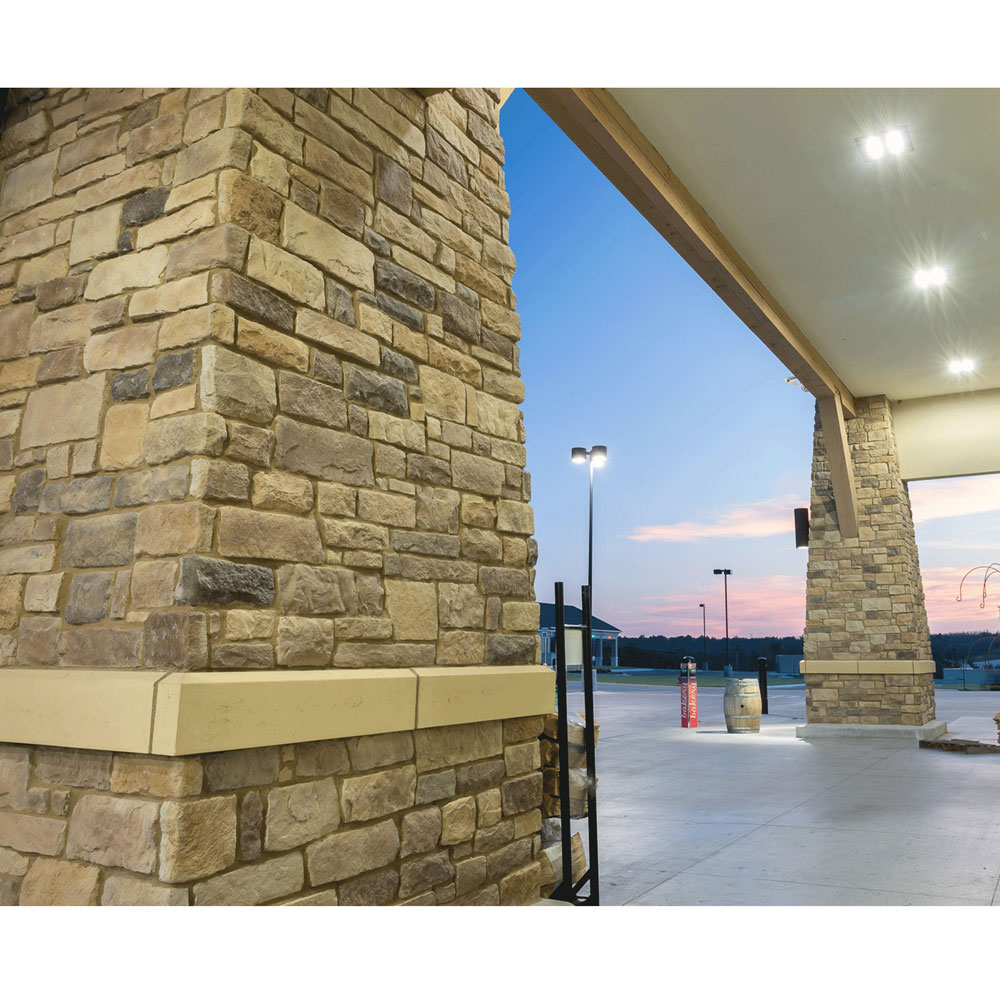

Limestone is a traditional stone that exudes a classic elegance, perfect for adding a touch of tradition to any space. This hand-dressed stone features a chiseled texture and is expertly crafted into a rectangular ashlar profile, giving it a rugged yet refined appearance.

Limestone corner molds are designed to complement the matching Limestone flat stone molds. Each limestone corner mold makes approximately 1.75 linear feet with a grout joint and is available in 3 unique version, with no stone repeats. Additional versions available upon request.

A corner plug (sold separately) can be used for 1-step corners. However, you can also create your own with melamine, plywood, etc. 1-step corners allow you to pour the corners in one step. Pour the long, horizontal end first, place the plug on the mold, then fill the open, short end and lightly vibrate.

In addition, our molds require NO release agent. This will save you money, time, and clean up, as well as easy, clean release of face color pigments, unlike plastic molds, urethane molds, and silicone molds.

Made in the USA, both materials and labor.

Manufactured Stone Basic Mixing Procedures Using A Pre-bagged Concrete Mix for your Limestone Corner Mold:

This is one suggestion for mixing the concrete for the limestone corner molds. There are many other instructions available online, including videos.

BE SURE TO USE A CONCRETE MIX THAT CONTAINS PORTLAND CEMENT. We recommend Sakrete Maximizer, as it has lightweight aggregate, is high strength, and yields more product, but there are many kinds you can use. Follow the manufacturer’s instructions for mixing.

If using pigment, add desired iron oxide pigment to mixer (100% pure, no additives). These can easily be found on Amazon, etc.

Additionally, a plasticizer can be added to reduce the amount of water in the mix. Pour into the molds which may already have coloring additives… NO RELEASE AGENT NECESSARY. Vibrate molds to release air bubble.

Finally, cure the concrete in the limestone corner molds for approximately 24 hours at the minimum of 70 degrees Fahrenheit before demolding. Higher humidity is desired. Molds can be covered with a tarp to retain more heat and humidity. Continue to cure demolded stones at 70 degrees or greater until ready.

Reviews

There are no reviews yet